On-Site Steel Reinforcement Installation: The Key to Structural Integrity

On-Site Steel Reinforcement Installation: The Key to Structural Integrity

Blog Article

Enhance Building Performance With Expert Steel Repairing

In the realm of building and construction, the function of specialist steel taking care of can not be overstated, as it straight affects both the architectural stability and effectiveness of projects. Experienced steel fixers apply their expertise to make certain specific placement and protected connecting of supports, which is essential in minimizing expensive errors and maximizing product usage. The difficulties faced in this important aspect of construction are complex and typically ignored. Comprehending these complexities may reveal strategies that could change job results, prompting a better assessment of just how such improvements can be implemented properly.

Value of Steel Correcting

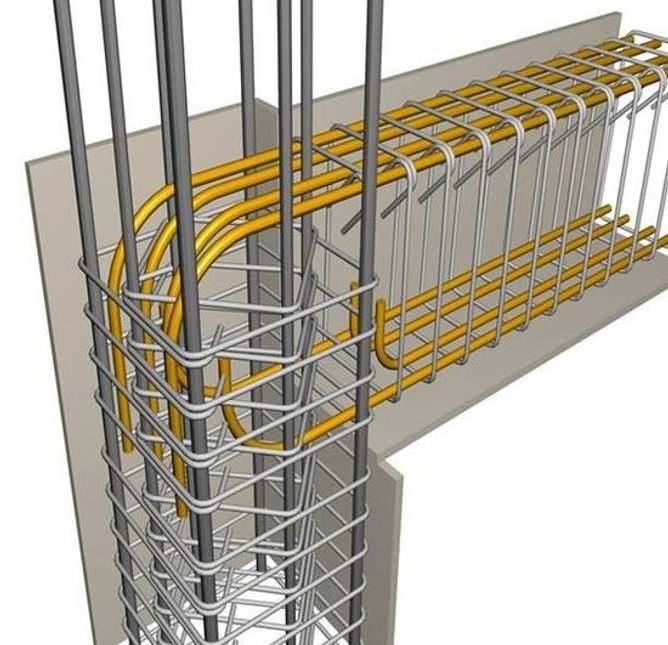

Why is steel repairing an important element in building and construction? Steel dealing with entails the positioning and safeguarding of steel reinforcement bars (rebars) within concrete frameworks, making sure architectural honesty and sturdiness.

Furthermore, the precision included in steel taking care of directly impacts the total quality of building. Precise positioning of rebars ensures that designs are complied with, minimizing the risk of structural weaknesses. In addition, steel taking care of adds to the effective transfer of tons within a framework, permitting for the building of much safer and more durable structures.

In addition to boosting structural efficiency, steel dealing with also contributes in optimizing building timelines. By making sure that steel support is correctly placed prior to concrete is poured, the threat of rework is substantially reduced. This structured technique not only saves time however additionally reduces general task expenses. Hence, recognizing the relevance of steel fixing is basic for experts in the construction industry, as it develops the backbone of safe and long-term frameworks.

Advantages of Expert Experience

In addition, knowledgeable steel fixers are adept at interpreting architectural and engineering plans. Their ability to properly equate designs into functional applications minimizes errors, therefore lowering pricey rework and task hold-ups. Expert competence likewise contributes to improved safety on website. Proficient steel fixers are trained in market requirements and best techniques, which aid to mitigate dangers related to steel job.

In addition, using expert solutions can bring about a lot more efficient use products. Specialists can optimize the quantity of steel needed, therefore lowering material prices and lowering waste. This performance not just benefits the spending plan however additionally aligns with lasting building and construction techniques.

Finally, depending on expert expertise promotes a collaborative environment among specialists, engineers, and designers, promoting smooth interaction and project execution. In general, the benefits of expert experience in steel taking care of are indispensable, considerably affecting the success and high quality of construction projects.

Techniques for Efficient Steel Dealing With

Effective steel taking care of strategies are vital for guaranteeing timely task conclusion and ideal structural performance. One of the primary methods involves specific preparation and design of rebar positionings based on structural drawings. Making use of advanced software for 3D modeling can assist in better visualization and coordination among the project group, lessening mistakes during installment.

Furthermore, utilizing suitable securing strategies, such as helpful resources wire connecting or mechanical couplers, can boost joint honesty and reduce labor time. Educating employees in best techniques for safety and efficiency is likewise vital, as skilled workers can perform jobs much more promptly and accurately.

Lastly, normal inspections during the installation procedure can help recognize and remedy possible issues early, avoiding expensive delays. By incorporating these techniques, building and construction projects can attain enhanced efficiency and enhanced structural quality, inevitably delivering much better results for customers and stakeholders.

Usual Challenges and Solutions

While applying effective strategies can significantly improve steel dealing with processes, various difficulties frequently occur that can impede development. One typical obstacle is the miscommunication between teams, resulting in mistakes in steel positioning and increased Continued rework. To address this, establishing clear interaction protocols and using innovative software for control can enhance precision and synergy.

Another significant issue is the irregularity in website problems. Unpredicted elements such as climate changes or ground instability can interrupt steel repairing procedures. An aggressive option involves conducting comprehensive website evaluations and having contingency plans in position to mitigate possible delays.

Additionally, labor lacks can prevent the prompt completion of steel fixing jobs. Buying training programs and cultivating a culture of ability development among employees can aid link this gap.

Last but not least, insufficient precaution can position dangers to both workers and the project timeline. Carrying out rigid security methods and regular training sessions can boost worker safety and reduce accident-related Discover More disturbances. By acknowledging these obstacles and implementing efficient options, building and construction experts can guarantee a more efficient and reputable steel taking care of procedure, eventually resulting in successful project results.

Effect On Job Timelines

The effect of steel choosing job timelines is an essential consideration for construction experts. Effective steel repairing directly affects the total timetable, as hold-ups in this stage can cause substantial obstacles in subsequent building and construction tasks. Appropriately performed steel dealing with ensures that the structural honesty of the job is attained in a prompt way, facilitating a smooth shift to the next phases of building and construction.

When steel fixing is performed by proficient specialists, the risk of errors and revamp is minimized, promoting adherence to the prepared timeline. On the other hand, poor steel fixing can result in costly hold-ups, calling for extra time for assessments and adjustments. The integration of advanced strategies and modern technologies in steel fixing, such as 3D modeling and prefabrication, can even more improve efficiency, enabling for quicker installation and decreased labor costs.

In addition, timely conclusion of steel repairing influences the scheduling of other professions, such as concrete ending up and pouring work. steel fixing. By focusing on professional steel dealing with, construction groups can properly manage their timelines, making sure jobs are delivered on time and within budget plan. Eventually, buying quality steel repairing solutions is vital for maintaining job momentum and attaining effective outcomes

Conclusion

Finally, expert steel fixing plays a crucial function in enhancing construction effectiveness by guaranteeing the exact placement and protected connecting of steel supports. The fostering of sophisticated methods, such as 3D modeling, simplifies the installment procedure, decreasing errors and revamp. Cooperation among designers, contractors, and designers better strengthens job outcomes, inevitably adding to the architectural stability and durability of concrete frameworks. Prioritizing professional knowledge in steel taking care of is necessary for the success of building tasks.

Steel dealing with involves the positioning and safeguarding of steel support bars (rebars) within concrete structures, making certain architectural honesty and durability. Knowledgeable steel fixers are educated in industry standards and finest techniques, which assist to mitigate risks connected with steel work.

By recognizing these challenges and carrying out efficient options, building and construction specialists can ensure a more reputable and reliable steel dealing with process, inevitably leading to successful job end results. (steel fixing)

By focusing on professional steel repairing, construction groups can properly handle their timelines, making certain tasks are provided on timetable and within budget plan.In conclusion, expert steel repairing plays an important duty in enhancing building and construction effectiveness by making sure the precise positioning and protected tying of steel supports.

Report this page